Smart ‘Ex-d’ motor design reduces total cost by supporting optimal performance, quick assembly, global use and fast time-to-market

Already for over 45 years, Elnor Motors supplies electric motors to leading fuel dispenser manufacturers around the world. Custom motors feature an explosion-proof (Ex-d) enclosure with integrated electric components. Smartly customized Elnor motors are designed for fast assembly, altogether reducing total cost significantly. The highly efficient winding design is tailored to the application and works reliably in multiple mains voltages all over the world. A broad range of Ex-certificates, covering our motor designs, avoids lengthy and costly certification procedures and facilitates export for our customers.

Reliably driving fuel dispensers

“We are proud to supply qualitative custom electric motors to the worldwide fueling system industry,” says Bart Demarsin, Elnor Technical Sales Manager. “Together with leading manufacturers, we have developed motors that reliably drive high-performance fueling systems. We focus on multiple aspects: global explosion-proof motor design & certification, efficient & robust winding design, easy motor mounting, and global distribution and use. Our lengthy experience enables us to deliver tried and proven solutions, also in more challenging markets with unstable electricity supply”

Elnor opted for designing explosion-proof motors following the ‘Ex-d’ protection level. The ‘Ex-d’ motor construction prevents the propagation of a potential internal explosion to the surrounding explosive atmosphere.

Dennis Verschueren, Elnor Technical Sales Engineer: “The custom explosion-proof Ex-d electric motors from Elnor have distinct advantages compared to more traditional standard Ex-d and Ex-e motor configurations, thanks to a design tailored to the application and the integration of electrical components that otherwise have to be installed separately.”

‘Ex-d’ design strategy reduces manual cabling work

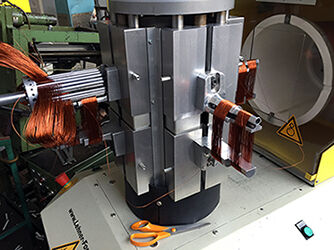

“Elnor develops its ‘Ex-d’ electric motor parts so that they can withstand extreme internal overpressure caused in the unlikely event of internal explosion, Dennis Verschueren explains. To sufficiently cool off the escaping gases, all connecting motor parts are designed with tighter tolerances and extended overlaps. During the development of fuel dispensing systems, Elnor flexibly collaborates with customers by implementing various design changes to meet a range of dimensional, electrical and explosion-proof requirements.

The use of custom ‘Ex-d’ motors eliminates separate terminal boxes and related manual cabling work. Dennis Verschueren: “From an economic viewpoint, smart customization means that the motors with customised drivetrain can be installed into the dispensers up to 5 times faster than before. This saves time and money, and allows fueling system manufacturers to respond quickly to changing customer requirements and market demands.”

Global certification & multiple mains

Elnor tailors its highly efficient winding design to the specific fuel dispensing application to ensure that the custom motors can reliably operate with multiple mains voltages across intercontinental markets.

Elnor has acquired certification to an extensive portfolio of standards, and is experienced in international certification. The Elnor motors are certified to ATEX, IECEx, Inmetro and UL standards for use in environments possibly containing combustible gases and vapours. Fully certified Elnor motors helps streamline customers’ efforts to acquire certification on fuel dispenser level.

In conclusion, Dennis Verschueren states: “These assets make Elnor a preferred partner to fueling system manufacturers which consider international expansion into existing and new market segments.”

Motor performance & production economics

Elnor’s custom motors are built to support fueling systems in multiple power variants for regular and higher-volume flow fueling as well as vapor recovery systems. Elnor supplies three-phase and single-phase motors which offer the required torque to instantly start pumping fuel in all circumstances,” Bart Demarsin explains. “In this regard, custom motor windings design is an advantage in addition to Elnor’s proprietary single phase motor design.”

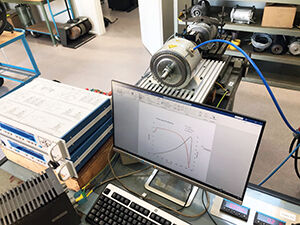

During development, specialists in Elnor’s advanced motor testing facility evaluate custom motor prototypes or complete machines using variable electric power, frequency, temperature, etc. Bart Demarsin: “It enables the motor engineering team to assess new custom motor prototypes fast and thoroughly. It can also be used for evaluating and troubleshooting.”

Reliable and affordable motors timely delivered

The production facility of Elnor is equipped – with both infrastructure and staff – to manufacture and assemble your custom fuel dispensing motors. Carefully chosen key activities, such as producing windings, shafts and housings, take place in-house, which fits our DNA to fully control motor power, performance and dimensions. The meticulous work during Elnor’s in-house winding process and the sole use of highest quality components ultimately result in a long motor lifetime.

Bart Demarsin says: “As a result, fueling systems fitted with an Elnor motor consume less energy, contain fewer assembly parts, and maintain highest quality and reliability. We build custom motor series in short and flexible delivery times.”

“On the workfloor, Elnor opts for a smart mix of in-house production and outsourcing to specialized suppliers. By gradually increasing the level of automation, we continuously improve production efficiency and capacity, while maintaining full motor design flexibility. Our vertically integrated production also enables us to quickly deliver a custom motor prototype, or quickly shift between production batches of divergent quantities. Overall, fueling system manufacturers value our capacity to execute production series on-order and in-house to realize short lead times for their fuel dispensing motors.”

コメント